The Peiler Convection Recuperator

The Peiler Turbomant

The Peiler Radiation Recuperator

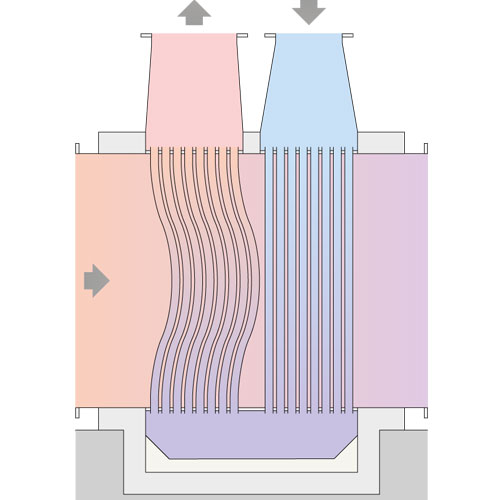

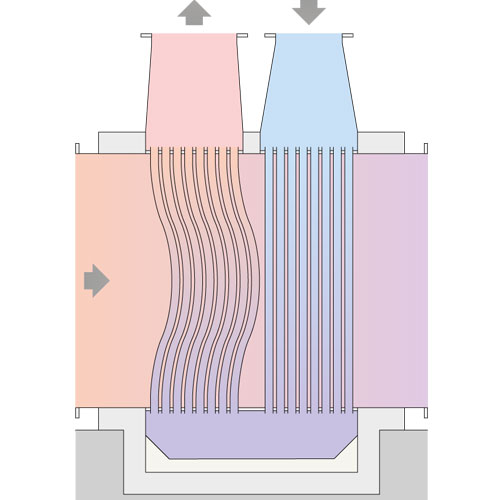

The Peiler Convection Recuperator

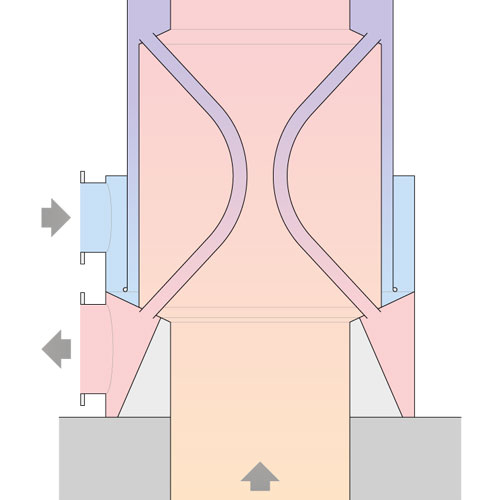

The Peiler Turbomant

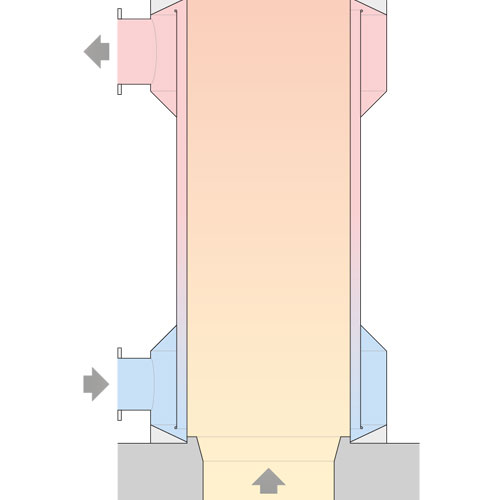

The Peiler Radiation Recuperator

The term “convection” denotes the transport of heat in liquids or gases through macroscopic material flows. Such an exchange of heat occurs in a Peiler Convection Recuperator: cooling air currents are passed in a large number of pipes past the exhaust gas current in such a way that they ensure the rapid removal of the heat.

Peiler Convection Recuperators can be used on all types of furnace if it is ensured that no aggressive substances are present in the exhaust emissions. The Convection Recuperator itself has a relatively favourable thermal efficiency level if the exhaust gas temperatures are within a low range.

The Convection Recuperator can be ideally adapted to operating requirements by dividing up the pipe systems into materials of the same or different qualities. The fact that groups or bundles of pipes can be easily replaced makes this type of recuperator simple to repair. The Convection Recuperator works economically at exhaust gas temperatures up to 1,000 °C where air preheating temperatures up to 650 °C and tube wall temperature up to 850 °C can be reached.

The Peiler Convection Recuperator is

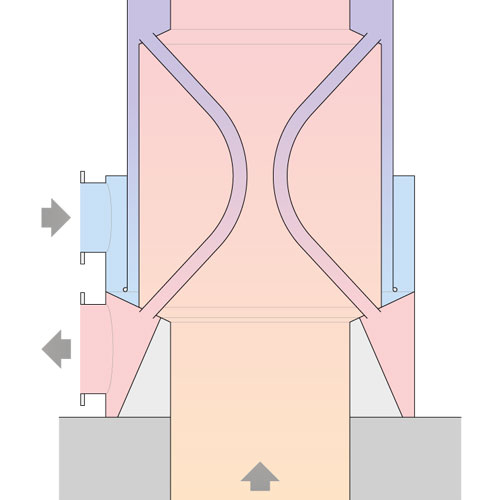

used onThe type of Peiler recuperator known as the Turbomant combines the mode of operation of a Radiation Recuperator with that of a Convection Recuperator. In a double-walled casing pipe additional pipes are incorporated on the inside. The turbulence of the exhaust gas in the interior pipe cage results in high convective heat transmission, both in the pipe bundle itself and on the internal wall of the double casing. The Turbomant does not therefore have the disadvantages of an exclusive Radiation Recuperator, in which the heat transmission capacity falls considerably with the temperature of the exhaust gases, but does not however reach its degree of stability if corrosive constituents of the exhaust gases attack the material.

One advantage is its external cylindrical shape, which allows it to be installed not only above furnaces, above the steel mill floor, but also in a sloping waste gas system. The Peiler Turbomant works economically from an exhaust gas temperature of 1,100 °C.

The Peiler Turbomant is used on

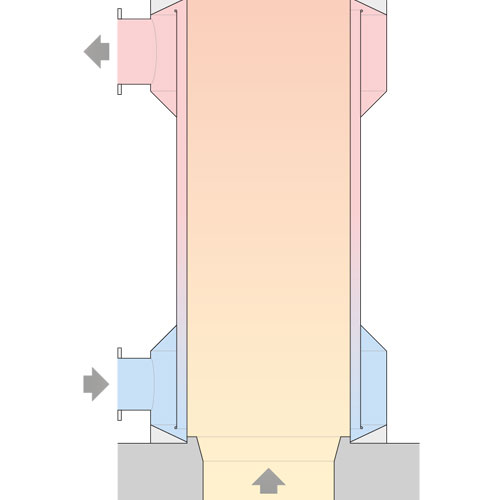

The Peiler Radiation Recuperator leads away heat in a single double-walled tube. Its robust construction and the smooth inner wall of the pipe makes it suitable for use in conjunction with waste gases with temperatures of more than 1,000 °C and waste gases containing particularly aggressive constituents. Its durability under these conditions is far superior to that of other types of recuperator.

The Peiler Radiation Recuperator is used on